| Type | Ap (mm) | Fn (mm/rev) | Grade | |||||||||||

| CVD | PVD | |||||||||||||

| VK3020 | VK3040 | VK1015 | VK1025 | VK1824 | VK1825 | VK1525 | VK1828 | VR1010 | VR1520 | VR1525 | VR1029 | |||

| XNEX080608TR-GL | 0.80-8.00 | 0.10- 0.30 | O | • | O | • | • | O | ||||||

| XNEX080612TR-GL | 0.80-8.00 | 0.10- 0.30 | O | • | O | • | • | O | ||||||

| XNEX080608TR-GM | 0.80-8.00 | 0.10- 0.30 | O | • | O | • | • | O | ||||||

| Length | Size(mm) | |

| L | S | |

| 8 | 7.5 | 6.45 |

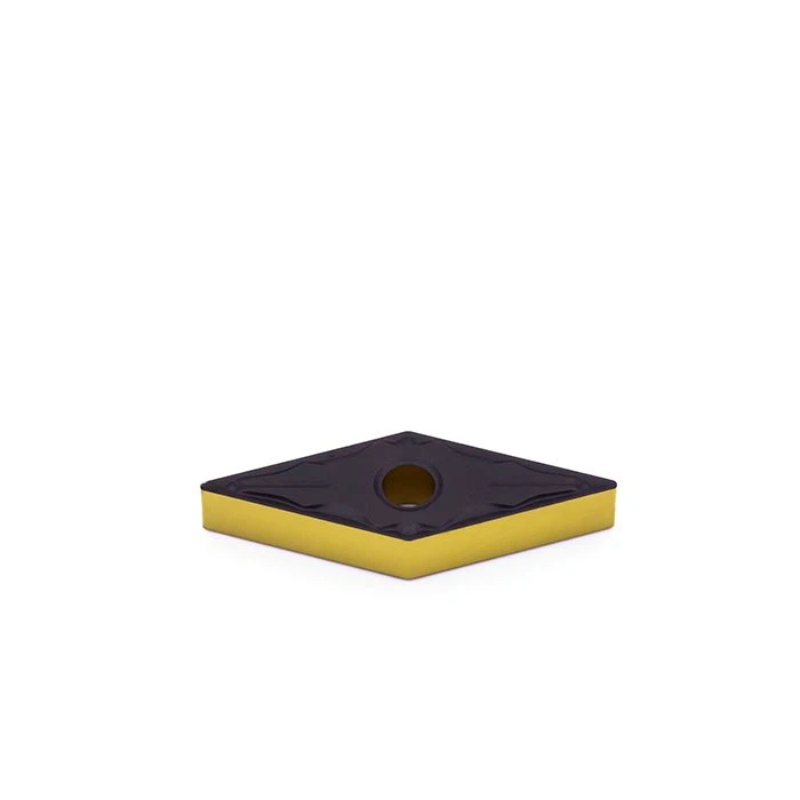

Our shoulder milling inserts are top-of-the-line CNC carbide inserts designed for superior performance in milling applications. With their exceptional cutting capabilities and durable construction, these inserts are suitable for a wide range of materials and provide excellent results.Versatile Milling: Our shoulder milling inserts are ideal for multiple milling applications, including face milling, shoulder milling, and ramping They excel in high-speed machining operations, ensuring efficient material removal with precision and accuracy Aerospace Industry: The aerospace industry demands high-quality machining solutions, and our shoulder milling inserts deliver Whether milling parts for aircraft structures, engine components, or landing gear, these inserts provide consistent performance, meeting the strict standards required in this industry Automotive Manufacturing: Precision and efficiency are key in automotive manufacturing, and our shoulder milling inserts deliver on both fronts From machining engine blocks to creating intricate mold cavities, these inserts offer reliable performance, reducing manufacturing costs and increasing productivityOur shoulder milling inserts are top-of-the-line CNC carbide inserts designed for superior performance in milling applications With their exceptional cutting capabilities and durable construction, these inserts are suitable for a wide range of materials and provide excellent results Cutting Edge Durability: Our shoulder milling inserts are constructed from high-quality carbide materials, ensuring exceptional durability and long tool life This durability reduces the frequency of insert changes, saving both time and money for users Excellent Chip Control: The unique chip breaker design incorporated into our shoulder milling inserts provides excellent chip control and evacuation The chips are efficiently directed away from the cutting zone, minimizing the risk of tool damage and ensuring smooth machining operations High Feed Rates: With their advanced geometry and cutting edge design, our shoulder milling inserts allow for high-feed machining This enables faster material removal rates, reducing cycle times and increasing overall productivityPrecision Ground Inserts: Our shoulder milling inserts are manufactured with precision ground cutting edges, ensuring clean and accurate cuts every time This precise cutting action results in superior surface finishes and dimensional accuracy Multiple Insert Grades: We offer a range of insert grades to suit different machining requirements Whether machining steels, stainless steel, cast iron, or other materials, we have the right insert grade to optimize performance and achieve optimal results Easy Insert Replacement: Our shoulder milling inserts are designed for easy replacement, minimizing machine downtime during tool changes The inserts are securely held in place and can be quickly replaced without the need for specialized tools Invest in our shoulder milling inserts to enhance your CNC carbide milling experience With their exceptional cutting capabilities, durability, and ease of use, these inserts will undoubtedly optimize your milling operations, increasing productivity and achieving superior results Trust our expertise and elevate your milling process to new heights with our shoulder milling inserts

Our shoulder milling inserts are top-of-the-line CNC carbide inserts designed for superior performance in milling applications. With their exceptional cutting capabilities and durable construction, these inserts are suitable for a wide range of materials and provide excellent results.Versatile Milling: Our shoulder milling inserts are ideal for multiple milling applications, including face milling, shoulder milling, and ramping They excel in high-speed machining operations, ensuring efficient material removal with precision and accuracy Aerospace Industry: The aerospace industry demands high-quality machining solutions, and our shoulder milling inserts deliver Whether milling parts for aircraft structures, engine components, or landing gear, these inserts provide consistent performance, meeting the strict standards required in this industry Automotive Manufacturing: Precision and efficiency are key in automotive manufacturing, and our shoulder milling inserts deliver on both fronts From machining engine blocks to creating intricate mold cavities, these inserts offer reliable performance, reducing manufacturing costs and increasing productivityOur shoulder milling inserts are top-of-the-line CNC carbide inserts designed for superior performance in milling applications With their exceptional cutting capabilities and durable construction, these inserts are suitable for a wide range of materials and provide excellent results Cutting Edge Durability: Our shoulder milling inserts are constructed from high-quality carbide materials, ensuring exceptional durability and long tool life This durability reduces the frequency of insert changes, saving both time and money for users Excellent Chip Control: The unique chip breaker design incorporated into our shoulder milling inserts provides excellent chip control and evacuation The chips are efficiently directed away from the cutting zone, minimizing the risk of tool damage and ensuring smooth machining operations High Feed Rates: With their advanced geometry and cutting edge design, our shoulder milling inserts allow for high-feed machining This enables faster material removal rates, reducing cycle times and increasing overall productivityPrecision Ground Inserts: Our shoulder milling inserts are manufactured with precision ground cutting edges, ensuring clean and accurate cuts every time This precise cutting action results in superior surface finishes and dimensional accuracy Multiple Insert Grades: We offer a range of insert grades to suit different machining requirements Whether machining steels, stainless steel, cast iron, or other materials, we have the right insert grade to optimize performance and achieve optimal results Easy Insert Replacement: Our shoulder milling inserts are designed for easy replacement, minimizing machine downtime during tool changes The inserts are securely held in place and can be quickly replaced without the need for specialized tools Invest in our shoulder milling inserts to enhance your CNC carbide milling experience With their exceptional cutting capabilities, durability, and ease of use, these inserts will undoubtedly optimize your milling operations, increasing productivity and achieving superior results Trust our expertise and elevate your milling process to new heights with our shoulder milling inserts